Evolution of Mechanical Fingerspelling Hands

|

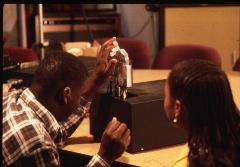

| In 1985, the Rehabilitation Engineering Center of The Smith-Kettlewell Eye Research Foundation sponsored a class project conducted by four graduate students in the Department of Mechanical Engineering at Stanford University to design and fabricate an improved state-of-the-art fingerspelling hand [2, 3, 4, 5, 6, 7]. Its major goal was to develop a system with improved timing and easily modifiable finger positions. These qualities were realized in a new robotic fingerspelling hand named "Dexter." |

Figure 2 - Dexter Fingerspelling Hand |

Dexter's mechanical hardware:

Dexter looked like a mechanical version of a rather large human hand projecting vertically out of a box. The four machined aluminum fingers and a thumb were joined together at its palm. All digits operated independently of each other and had a range of motion comparable to human fingers. The thumb was jointed so as to allow it to both sweep across the palm as well as move in a plane perpendicular to it. A pneumatic rotary actuator allowed the palm to pivot in a rotary fashion around a vertical steel rod much the way a human hand can pivot from the wrist - except that a full 180 degrees could be achieved by Dexter.

All Dexter's finger and thumb motions were actuated by drive cables. Pneumatic cylinders pulled these cables which flexed the individual fingers and thumb, while spring-driven return cables extended the fingers. The cylinders, in turn, were activated by air pressure controlled by electrically operated valves. These valves were controlled by a microcomputer system. The actuating equipment and valves were housed in two separate assemblies below the hand.

Dexter's computer hardware:

The original student design was based on an Intel 8085 STD-bus "target system" used in ME218 (Smart Product Design Course) at Stanford. It consisted of the 8085 microcomputer, Forth programming language, memory, and counter/timer support. The timer generated the signals that determined the rate of hand motion and how long each finger position was to be held. The additional circuitry needed to control Dexter was fabricated on an STD card which plugged into the target system card cage. A single external 12 volt power supply activated the 22 valves under computer control. Digital output port latches received data from the CPU, while Darlington power transistors provided sufficient current to activate the electrically controlled valves. Letters to be displayed on the hand were entered on an IBM-PC computer's keyboard which was connected by a serial link to the target hardware.

Dexter's hardware was subsequently revised at the Rehabilitation Research and Development Center (RR&D) to consist of a Z80 microprocessor card, two medium-power driver cards, and a high-current DC power supply all housed in an STD bus card cage. The CPU card itself contained counter-timers, memory, and serial interfaces. Commercial medium-power DC driver cards replaced the student-built wire-wrapped version and the power supply for operating the pneumatic valves was included within the STD chassis. An Epson HX-20 laptop computer's keyboard and display were employed to communicate user messages over a serial link to the self-contained target system.

Dexter's software:

The Forth programming language was chosen because: 1) its design cycle is approximately eight times shorter than assembly language, 2) it is an interactive and compact high-level language that can employ assembly language for critical timing and interrupt service routines, 3) it uses a standard host computer connected by a serial port to the target hardware for development, and 4) the application program can be stored in non-volatile memory after it is fully tested.

The student-designed Forth software was substantially updated by RR&D to 1) execute from non-volatile memory, 2) accommodate menu-driven alteration of critical parameters such as timing variables, 3) allow new characters typed on the keyboard to be accepted while previous ones were being fingerspelled, and 4) incorporate both modem and serial input of characters.

Dexter's operation:

The microcomputer and its associated software controlled the opening and closing of the bank of valves which directed air pressure to specific pneumatic cylinders which pulled on the drive cables which were the "tendons" of the fingers. As a message was typed on a keyboard, each letter's ASCII value was used by the software as a pointer into an array of stored valve control values. The states (open or closed) of all 22 valves were specified by three bytes. Two to six valve operations, each separated by a programmed pause, were needed to specify the finger movements corresponding to a single letter. The hand could produce approximately two letters per second, each starting from and returning to a partially flexed neutral position.

An additional bit in the valve control byte triad was used by the software to determine whether the current finger position was an intermediate or final letter position. Different programmed pause times were associated with each of these two situations.

Although the mechanical hand could not exactly mimic the human hand in fingerspelling all the letters (such as the special wrist and arm motions required in J and Z), the fact that Dexter always produced the same motions for a given letter was an important factor influencing its intelligibility. The inter-letter neutral position was another unnatural feature of the design that did not accurately reflect human fingerspelling and limited the speed of letter presentation. Despite these shortcomings, users of Dexter had little difficulty in accommodating to it.

Result: Testing Dexter

Deaf-blind clients of Lions Blind Center (Oakland, CA) served as subjects for the initial testing of Dexter. They were able to identify most of the letters presented by the robotic hand without any instructions, and in less than an hour were correctly interpreting sentences. Equally important was their positive emotional reaction to the hand. They seemed to really enjoy using it and seemed to be intrigued by its novelty. There were no negative comments made concerning its mechanical nature or any other aspect of the system.

Method: Dexter-II

| Dexter-II was built by a second Stanford student team in 1988 as a second- generation computer-operated electro-mechanical fingerspelling hand [8, 9]. This device, like its predecessor, translated incoming serial ASCII (a computer code representing the letters and numbers) text into movements of a mechanical hand. Dexter-II's finger movements were felt by the deaf-blind user and interpreted as the fingerspelling equivalents of the letters that comprise a message. Dexter-II was approximately one-tenth the volume of the original Dexter mechanical system. It was designed by three Stanford graduate mechanical engineering students and employed DC servo motors to pull the drive cables of a redesigned hand, thereby eliminating the need for a supply of compressed gas. A speed of approximately four letters per second, double that of the original design, could be achieved with the improved design. |

Figure 3 - Dexter-II Fingerspelling Hand |

Mechanically, the hand (a right hand the size of a 10 year old) was oriented vertically on top of a enclosure housing the motors. Each finger could flex independently. In addition, the first finger could move away from the other three fingers in the plane of the hand (abduction). The thumb could move out of the plane of the palm (opposition). Finally, the wrist could flex. Each hand motion was driven by its own servo motor connected to a pulley. Wire cables anchored at the hand's fingertips and wound around pulleys served as the finger's "tendons". As the motor shafts were powered, they turned the pulleys, pulling the cables, to flex the fingers. Torsion springs at the "knuckles" separating the Delrin finger segments provided the force to straighten the fingers when the motors released tension on the cables.

Dexter-II's computer used the STD-bus enclosure, Z80 microprocessor card, and Epson HX-20 computer from Dexter. Two commercial counter timer cards replaced the medium-power driver cards and were used to produce the pulse- width modulated waveforms required to control the DC servo motors. In operation, a message was typed on a keyboard (the Epson HX-20) by an able- bodied person. Each letter's ASCII value was used by Dexter-II's computer software to access a memory array of stored control values. This data stream programmed the pulse-width modulation chips to operate the eight servos and flex the fingers. The resulting coordinated finger movements and hand positions were felt by the deaf-blind communicator and interpreted as letters of a message.

Result: Testing Dexter-II

Dexter-II was first tested by a deaf-blind woman who is extremely proficient at "reading" tactile fingerspelling. She provided many suggestions for improving Dexter-II's letter-shape configurations. Later, it was introduced to twelve deaf-blind people during an annual retreat in Sacramento.

In June of 1989, about twenty deaf-blind attendees at the annual Deaf-Blind Conference in Colorado Springs had a chance to experience Dexter-II. The device was also exhibited at the 1989 RESNA Conference in New Orleans and at the InvenTech meeting in Anaheim, CA in September, 1989. In all cases, the deaf-blind individuals' ability to initially understand Dexter-II varied considerably. Some were able to understand Dexter-II immediately, while others had trouble translating a few letters.

Although neither Dexter nor Dexter-II could exactly mimic human hand movements in fingerspelling all the letters, they were able to display close approximations that have proven to be easy to learn by deaf-blind users. An advantage of Dexter-II's mechanical system was that it always produced the same motions for a given letter - an important factor in recognizing its fingerspelling "accent".

Method: Fingerspelling hand for Gallaudet

| In 1992, Gallaudet University (Washington, DC), with funding from NIDRR, contracted for the design and construction of two third generation fingerspelling hands for clinical evaluation [10, 11]. These units were to be smaller, lighter, and more intelligible than previous designs. The effort involved two facilities: RR&D Center designed the new mechanical and computer systems, while the Applied Science and Engineering Laboratories (ASEL) (Wilmington, DE) provided critical hand position data and addressed telephone interface access issues. |

Figure 4 - Fingerspelling Hand for Gallaudet |

Fingerspelling hand for Gallaudet mechanical design:

In this design, as in Dexter-II, each hand motion was driven by a servo motor connected to a pulley. A cable was wound around the pulley, routed up the finger, and attached to its tip. The fingers themselves were constructed of Delrin segments attached to each other by a strip of carbon fiber. The carbon fiber provided the flexible hinge and restoring force necessary to extend the finger. When the motor shaft and pulley rotated, the cable was pulled and the finger flexed. When the motor shaft rotated in the other direction, the tension on the cable was released and the finger straightened.

Fingerspelling hand for Gallaudet computer hardware design:

A Z180 SmartBlock (Z-World, Davis, CA) 8 bit microcontroller accepted RS232 serial data and choreographed hand motion by controlling eight DC servo motors. The controller itself was compact enough to be packaged within the hand's enclosure.

Fingerspelling hand for Gallaudet computer software design:

The Forth programming language provided a simple user interface, allowed modifications to the finger positions, and permitted the system parameters to be altered. Fingerspelling movements in this version were much more fluid due to the elimination of the inter-letter neutral position. The software includes two finger position tables for each letter pair. One table is permanently installed, while the other can be altered using a built-in editor. This facility permits movements to be changed to enhance a particular letter pair's readability. Fingerspelling speed was adjusted by a six position rotary switch. The first five positions selected increasing speeds by altering the length of the pauses between letters, while the final position offered a programmable speed.

Result: Fingerspelling hand for Gallaudet testing and evaluation

ASEL tested and configured the fingerspelling hands for use with TDDs. The letters were further optimized for improved recognition. Nine deaf-blind people tested the hands over a two month period at Gallaudet. One individual was able to interpret all ten simple sentences without error. Other users were able to understand 70% of the sentences. Comparable performance was achieved with single isolated letters. The users identified confusing letter combinations and suggested improvements for a commercial prototype [12].

Method: Ralph

| A fourth generation fingerspelling hand called Ralph (for Robotic ALPHabet) has been constructed by RR&D to serve as a basis for technology transfer and commercialization. Specifically, this design implemented an improved mechanical system. Ralph's mechanical design: Ralph's design is similar to the hands designed for Gallaudet. In this device, however, a new mechanical system replaces the pulleys and carbon fiber strips. Each hand motion is driven by a servo motor connected by a lever arm to a rod. The rods push and pull a system of linkages that flexes the individual fingers and the wrist. The elimination of the pulleys makes Ralph more compact and able to fingerspell faster. Its fingers are actively extended, unlike Dexter-II or the Gallaudet hands. |

Figure 5 - Ralph Fingerspelling Hand |

Ralph's computer design:

Ralph utilizes the same computer hardware as its predecessor and its Forth software is organized in 17 modules. These modules provide enhancements for the Forth kernel, an assembler (including routines that implement special I/O instructions used by the microcontroller), an ANSI display driver, serial port utilities, timer port utilities, clock utilities, servo motor pulse width modulation generation, speed switch driver, interrupt routines, input buffer software, timing control, hand data storage, fingerspelling algorithm, hand position editing support, and the user interface. As with the Gallaudet hand, Ralph's software provides a menu-driven user interface, allows the finger positions to be edited, and permits alteration of system parameters.

Ralph's operation:

Any device that produces RS232 serial data, including terminals, modems, computers, OCR scanners, speech recognizers, or modified closed caption systems, could be used to control Ralph. The user interface is implemented as a menu system which provides easy access to the unit's various functions including displaying and setting the microcontroller's parameters, testing the hand motions, editing hand position data, and entering letters to be fingerspelled.

In the fingerspelling mode, keypresses are entered on the keyboard. The hand's software translates these keypresses into commands for the DC servo motors. As the motor shafts rotate, they push/pull on the rods that connect to the fingers' mechanical linkages. It is by this coordinated series of motor commands that keyboard input is transformed into choreographed motion representing fingerspelling.

The mechanical system provides sufficient torque to move the fingers against the resistance of a user's hand, but not enough to cause any pain or injury if the user's finger happen to get caught under Ralph's. The servo motors simply stall when their torque limit is exceeded.

Result: Ralph's testing and evaluation

Over a two-day period at ASEL, Ralph was evaluated for approximately 8 hours by two individuals. One was familiar with the Gallaudet fingerspelling hand and was completely deaf and blind. The other had not used mechanical fingerspelling hands before and had some residual sight and hearing capabilities.

They both reported trouble with some letters, but the first user was able to correctly identify isolated characters over 75% of the time.

When short sentences were presented, the experienced user completely understood approximately 75% of the sentences. Furthermore, in each of the failures, after a second presentation, the sentence was either understood in its entirety or just one key word was misidentified.

Additionally, both users appreciated the new rounded design of Ralph's finger segments because they felt more natural than the hands built for Gallaudet.

Discussion: Technology transfer

Beyond evaluation, technology transfer issues must be addressed. The market for fingerspelling hands needs to be assessed. A collaborative effort with a manufacturer will be required to move this device out of the laboratory and into the hands of deaf-blind people. A potential manufacturer has been found in southern California. Current plans involve pursuing Small Business Innovative Research (SBIR) funding for technology transfer and the additional design changes to address remaining concerns identified during Gallaudet's evaluation.

A potential solution exists for the provision of fingerspelling hands to deaf-blind people. Within California (and some other states), all telephone subscribers support a fund which provides telephone access equipment for persons with disabilities. Under this program, approved commercial versions of this fingerspelling hand could be furnished at no charge to deaf-blind people.

Research has also been done on a "Talking Glove" [13]. This device consisted of an instrumented glove worn by a deaf-blind person that sensed the flex of each finger. Its pattern matching software translated the wearer's fingerspelling gestures into letters which could be displayed or vocalized by a speech synthesizer. This system could provide an expressive communication channel for Ralph's users.

Conclusion:

Ralph was intended to serve deaf-blind users as a complete receptive communication system, not just a means of receiving information in face-to- face situations. Its ability to respond to computer input means it can be interfaced to a TDD to provide deaf-blind people with telephone communication. It can also be connected to computers to provide improved vocational and avocational potential to the deaf-blind community.

All encounters with Ralph and previous fingerspelling hands have been enthusiastic, positive, and at times, highly emotional. The increased communication capability and ability to "talk" directly with people other than interpreters are powerful motivations for using fingerspelling hands. They have the potential to provide deaf-blind users with untiring personal communication at rates approaching that of a human interpreter.

A commercially available product may help alleviate some of the extreme isolation experienced by people who are deaf and blind. It is a device which performs a worthy task - that of enabling human beings to communicate with each other.

References:

| 1. | Laenger, Charles J., Sr.; and Peel, H. Herbert, `Further Development and Tests of an Artificial Hand for Communication With Deaf-Blind People', Southwest Research Institute, March 31, 1978. |

2. |

Danssaert, John; Greenstein, Alan; Lee, Patricia; and Meade, Alex, `A Finger-Spelling Hand for the Deaf-Blind, ME210 Final Report', Stanford University, June 10, 1985. |

3. |

Gilden, Deborah, `A Robotic Hand as a Communication Aid for the Deaf- Blind', Proceedings of the Twentieth Hawaii International Conference on System Sciences, 1987. |

4. |

Gilden, Deborah and Jaffe, David L., `Dexter - A Mechanical Finger- Spelling Hand for the Deaf-Blind', Rehabilitation Research and Development Center Progress Reports, 1986. |

5. |

Gilden, Deborah and Jaffe, David L., `Dexter - A Helping Hand for Communicating with the Deaf-Blind', Ninth Annual RESNA Conference, Minneapolis, MN, 1986. |

6. |

Jaffe, David L., `Speaking in Hands', SOMA: Engineering for the Human Body, Volume 2, Number 3, October, 1987, pp 6-13. |

7. |

Gilden, Deborah and Jaffe, David L., `Dexter - a Robotic Hand Communication Aid for the Deaf-Blind', International Journal of Rehabilitation Research, 1988, II (2), pp198-199. |

8. |

Jaffe, David L., `Dexter II - The Next Generation Mechanical Fingerspelling Hand for Deaf-Blind Persons', Proceedings of the 12th Annual RESNA Conference, New Orleans, June, 1989. |

9. |

Jaffe, David L., `Dexter - A Fingerspelling Hand', OnCenter - Technology Transfer News, Volume 1, Number 1, June, 1989. |

10. |

Jaffe, David L., `Third Generation Fingerspelling Hand', Proceedings of the Technology and Persons with Disabilities Conference, Los Angeles, CA, March, 1993. |

11. |

Jaffe, David L., `The Development of a Third Generation Fingerspelling Hand', 16th Annual RESNA Conference, Las Vegas, NV, June, 1993. |

12. |

Harkins, Judith E., Korres, Ellie, and Jensema, Carl J., `Final Report - A Robotic Fingerspelling Hand for Communication and Access to Text for Deaf-Blind People', Gallaudet University, 1993. |

13. |

Kramer, James and Leifer, Larry, `An Expressive and Receptive Communication Aid for the Deaf, Deaf-Blind, and Nonvocal', Proceedings of the Annual Conference, IEEE Engineering in Medicine and Biology Society, Boston, 1987. |

Other references:

Ouellette, S., `Deaf-blind Population Estimates', In D. Watson, S. Barrett, and R. Brown (Eds.), A Model Service Delivery System for Deaf-Blind Persons. Little Rock, AK: University of Arkansas, Rehabilitation Research and Training Center on Deafness/Hearing Impairment., (not dated).

Reed, C.M., Delhorne, L.A., Durlach, N.I., and Fischer, S.D., `A Study of the Tactual and Visual Reception of Fingerspelling', Journal of Speech and Hearing Research, 33, 786-797.

Funding:

Dexter's design and development was conducted under DOE-NIHR Grant No. G008005054, with assistance from The Smith-Kettlewell Eye Research Foundation.

Dexter II was developed with VA RR&D Core funding.

Gallaudet Hand support was provided by NIDRR (Project H133G80189-90) under contract to PAIRE (Palo Alto Institute for Research and Education) and supervised by Gallaudet University.

Ralph was supported by VA RR&D Core funds through its Technology Transfer Section.

Acknowledgements:

The following people and facilities were involved in the evolution of mechanical fingerspelling hands. This effort would not have been possible without their ideas, energy, and commitment.

- Rehabilitation Research and Development Center

- David L. Jaffe

- Douglas F. Schwandt

- James H. Anderson

- Stanford student group - Dexter

- John Danssaert

- Alan Greenstein

- Patricia Lee

- Alex Meade

- Stanford student group - Dexter II

- David Fleming

- Gregory Walker

- Sheryl Horn

- Smith-Kettlewell Eye Research

- Deborah Gilden

- Gallaudet University

- Judith E. Harkins

- Ellie Korres

- Carl J. Jensema

- Applied Science and Engineering Laboratories

- Richard Foulds

- William Harwin

- Timothy Gove

- Palo Alto Institute for Research and Education

- David D. Thomas

- University of Capetown Medical Center

- David A. Boonzaier