1996 Project Reports | Home |

Contents | Previous |

Assistive Technology Projects - Development of Prototypes

James Anderson, JEM; David A. Brown, PhD, PT; Charles G. Burgar, MD; Deane

Denney; Arden Farey; Vincent R. Hentz, MD; David L. Jaffe, MS; Deborah Kenney,

MS, OTR; Maurice LeBlanc, MS; Stephanie O'Leary, MS, OTR; Eric E. Sabelman,

PhD; Alvin Sacks, PhD; Douglas Schwandt, MS; Jaime S. Vargas, MS; Peter Werner,

MD; Conal B. Wilmot, MD

Technology Transfer

Guidelines

Sacks

This document was prepared in an effort to assist and inform those in the

DVA who have responsibility for the transfer of technology from laboratory to

manufacturer. The guidelines organize and integrate relevant technology

transfer material. Appendices include references to the Federal Technology

Transfer Act, other pertinent legislation, Cooperative R&D Agreements and

Disclosure of Invention forms.

Thumb Control Environmental Control Interface

Jaffe, Burgar

The

Thumb Control is a single switch input environmental control interface for an

inpatient veteran with a brain stem injury. The user controls the system's

operation with a glove-mounted microswitch. The interface then operates the

nurse call, television, stereo, lamp, and computer. This system provides backup

to a commercial environmental control system (Ke:NX by Don Johnston) which is

used to run Macintosh computer programs, communicate with family and staff, and

access the Internet and World Wide Web. The main unit resides on an over-bed

table, has a backlit LCD display for night operation, and is constructed around

an inexpensive battery-powered microcontroller. Unique features of this device

include user control over many of its operational parameters including scan

rate, dwell time, and audio feedback as well as its ability to reboot the

Macintosh and activate the nurse call in the event of a computer failure. While

this initial prototype is a dedicated unit for a specific individual, its

features can be generalized for use by others and incorporated into future

commercial units.

Figure - Thumb Control Environmental Control

Interface.

|

Ultrasonic Head Control Interface

Jaffe

The Ultrasonic Head Control Unit is an interface serving people without

control of their arms or legs. The user's head position is calculated from

ranging data provided by two Polaroid ultrasonic transducers. The head position

information is then used for the realtime control of an electric wheelchair or

a computer's mouse. Tilts of the user's head off the vertical axis

(forward-backward, left-right) operate the wheelchair or move the screen

cursor. The primary advantage of this device is that it requires no mechanical

contact between the transducers and the user's head. The user, therefore, does

not feel "wired up". The interface is intuitive to use, unobtrusive,

cosmetically pleasing, and socially acceptable. Within the VA, the Technology

Transfer Section in Baltimore has completed a nationwide clinical study of

commercial prototype wheelchairs equipped with the interface (from Eureka Labs

in Sacramento) and is now funding a cooperative effort with the Cerebral Palsy

Research Foundation of Kansas to move this technology to the marketplace.

ERGO Knife

Kenney, LeBlanc, Anderson

The ERGO Knife is an ergonomic replacement for

the utility knife. Its design alleviates the often uncomfortable and tiring

positions of a regular utility knife and allows safe and easy cutting of flat

materials, even while seated. The ERGO knife is ideal for cutting heavy duty

materials such as cardboard. Originally designed to aid therapists in cutting

splint plastic, it also fits a variety of industrial applications and home

needs for both able bodied and disabled users. Corporate partners are currently

being sought for commercialization of this product.

Figure - The ERGO knife cutting a plastic

sheet

|

SkillSet Office Tools

Vargas, Anderson, Denney, O'Leary

SkillSet is a family of inexpensive tools that

help people with limited hand function work effectively in the modern office

environment. Included are devices for handling diskettes, papers, paper clips,

file folders, paperfolding, and staple removing. SkillSet can enhance the

productivity and independence of office workers, professionals, students -

anyone who works with documents or computers. Each tool in the SkillSet is

designed around a specific task, making it easy to build customized tool kits.

SkillSet tools work with standard office equipment and supplies, making them an

attractive investment for employers wishing to meet ADA requirements

cost-effectively.

Clinical testing in the Spinal Cord Injury Service will assess SkillSet's

usefulness and market potential. Commercial partners are being sought to

manufacture and distribute SkillSet.

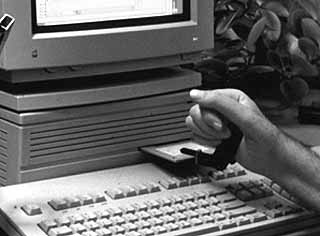

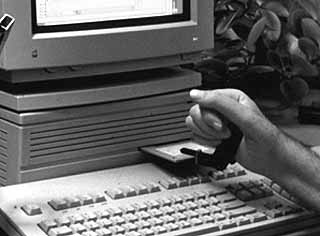

Figure - SkillSet's diskette handling tool

|

Beverage Dispenser

Anderson, O'Leary

Persons with quadriplegia typically do not

have use of their arms or hands so they depend on others to help them drink.

This is a labor intensive task for caregivers and can diminish the user's

independence and self esteem.

The Beverage Dispenser provides individuals with quadriplegia a means to

drink on their own. The dispenser consists of two major pieces. The first is a

cloth bag that holds a closed beverage container and hangs by straps on the

back of the user's wheelchair, out of the way. The gravity support prevents

spills when the chair is reclined. The second element is a fully adjustable

piece of plastic tubing that supports the straw from the beverage container to

the vicinity of the user's mouth. The caregiver only has to load the cloth bag

with the beverage of choice and position the tubing. The product is currently

in the field evaluation stage. Upon successful completion of clinical trials,

the product design will be offered to manufacturer/marketing vendors for

commercialization.

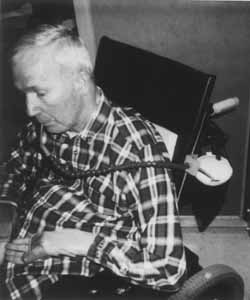

Figure - The beverage dispenser mounted on the

back of the wheelchair.

|

Crutch Caddies

LeBlanc, Kenney

When using forearm crutches, people with

mobility impairments have difficulty carrying objects such as papers, soda

cans, keys, etc. Although canvas bags for underarm crutches with double

uprights are already commercially available, there are no such products for

forearm crutches. We have developed crutch caddies which clip onto the tubular

upright of the forearm crutch.to allow these users to carry personal objects.

One caddy version is flat to carry papers; another is round to carry soda cans.

After clinical testing, a technology transfer effort will seek to bring the

crutch caddies to market.

Figure - The Crutch Caddy is mounted on a

forearm crutch.

|

Wheelchair Rear-view Mirror

Schwandt, Anderson, Farey

A wheelchair rear-view mirror serves

individuals who have difficulty looking behind them while backing up. The

mirror is compact and unobtrusive, yet provides the user with vision toward the

rear of the wheelchair, especially directly behind the large wheels. The convex

mirror provides a wider field of vision than a flat mirror. Initial prototyping

focused on the selection of a small mirror and on methods of attaching it to

the wheelchair. A two inch diameter adhesive-backed convex mirror, commonly

added to automobile side mirrors was purchased. Originally, the mirror was

attached to the wheelchair using dental accessory tubing which could be shaped

by hand to position the mirror correctly. Two small, black, Delrin blocks were

machined to hold each end of the adjustable tubing, one block adhering to the

back of the mirror with adhesive, and the other attaching to the wheelchair

frame tube with wire ties. Although the dental accessory tubing was found to be

too flexible, subject to vibration, and unable to hold its shape, commercially

available bike helmet mirrors proved to be easily adaptable to the task. This

design is currently being evaluated by wheelchair users in the Rehab R&D

Center and Spinal Cord Injury Service.

Figure -A small adjustable rearview mirror

mounts to a wheelchair's frame tube.

|

Boat Access Gangway

Schwandt, Anderson

The DDP, while evaluating the process of orphan product development, became

aware of a unique accessibility problem.

People who live and work onboard a boat often require a high degree of

physical dexterity and strength to board and disembark; an ability often lost

after a disabling event. A veteran who suffered a stroke had a wooden staircase

built which sat beside his cabin cruiser and allowed him access to his boat.

But because the staircase could not go onboard, he could only leave his boat at

its home dock where the staircase was permanently located. A gangway that could

be attached to the captain's boat, carried aboard, and be deployed at any dock

would enable him to disembark at any port that he visited.

A four step, four bar linkage aluminum

staircase was designed and built. The stair treads are twenty inches wide and

twelve inches deep, allowing full, stable support of the captain's feet in the

event he needs to rest on any stair step. The four bar linkage attaches to a

yoke that pivots on a fixed plate secured to the boat. The entire gangway can

be lifted to a horizontal position and rotated ninety degrees counterclockwise

to a stowed and securely fastened position on the aft side of the boat. This

process takes only a few minutes. Initial results from the field evaluation of

the gangway have demonstrated satisfactory operation in several locations where

the boat has docked. The captain continues to live and work onboard the boat,

but no longer feels trapped at dockside.

Because it is an orphan product and it is unlikely that a manufacturer would

commercialize it, our intention is to make the design drawings available to

others who could benefit from it. We will evaluate the response to offering the

product on a do-it-yourself basis and determine whether the approach is merited

for future projects. While the Rehab R&D Center does not routinely develop

devices for individual patients, projects like this provide valuable insight

into factors that must be considered when designing products for larger

populations of persons with disabilities.

Figure - A stowable stairway provides boat

access to individuals with limited mobility.

|

Method and Apparatus for Cyclocentric Ergometer

Exercise

Brown

There are many exercise devices that are used to strengthen lower extremity

muscles. It is important to find exercises for increasing strength in

functional weight-bearing tasks such as walking, running, and jumping while

minimizing the damage to joints that may occur with repetitive training of

these tasks. Currently available bicycle ergometers, although a good exercise

for minimizing joint loading stress, all involve some seating mechanism that

absorbs most of the body weight forces so that weight-bearing onto the

extremity is minimized. A Cyclocentric Ergometer Exercise (CEE) unit is under

development that overcomes many disadvantages of currently available devices.

CEE possesses a wide range of commercial properties. Since it is easy to use

and can provide training challenges to athletes as well as disabled persons, it

may be made available to the general gym workout market, home exercise market,

and the clinical rehabilitation market. Potentially, anyone interested in leg

strengthening exercises could benefit from using CEE.

Positioning and Transfer of Acute Spinal Cord Injury

Patients

Sabelman, Wilmot, Werner

The goal of this project was to design, fabricate, and test in laboratory

and clinical settings equipment to improve stabilization of cervical spinal

cord injury (SCI) patients during transport. SCI patients are exposed to risk

of further injury by unintentional spinal motion during transport by helicopter

to a specialized spinal center and during routine nursing, therapeutic, and

diagnostic procedures in the hospital.

We have designed an x-ray compatible carbon

fiber composite backboard and acceleration-independent cervical traction unit

for transporting SCI patients. Backboard/ traction systems have been in

clinical use since February, 1985, by the Stanford/Life-Flight for

inter-hospital helicopter transport and by Santa Clara Valley Medical Center

Dept. of Physical Medicine & Rehabilitation for in-hospital transport, and

since July, 1991, by REACH/MediPlane aeromedical transport service in Santa

Rosa, CA. Users report only minor problems related to counter-traction,

cleaning, and traction unit height adjustment. We are exploring collaboration

possibilities with the US Air Force Armstrong Laboratory, Brooks AFB, TX, in

setting design and test specifications for a new generation of equipment for

long-distance evacuation of military SCI casualties.

Figure - Loading (simulated) SCI patient in

traction on board BK-117 helicopter.

|

Implantable Fingertip Touch Sensation Prosthesis

Sabelman, Hentz

Loss of touch and pressure sensation may occur as a result of spinal cord

injury, brachial plexus trauma, diabetes or Hansen's disease. In order to

provide protective sensation and closed-loop servocontrol of grasp force, we

have studied preferred anatomical sites for implantable rather than externally

mounted touch sensors. We subsequently constructed mock-up sensors small enough

to be implanted, and built breadboard large-scale circuits for getting power to

and touch signals from implanted sensors.

The state-of-the-art of implantable sensors

has advanced to the point that transducers can be encased in glass tubes small

enough to inject through a large-bore hypodermic needle. This is essentially

the technology we propose to adapt: the pressure-sensing diaphragm, signal and

excitation voltage-conditioning circuits and output transmitter will be

constrained to fit within a 2 to 3 mm OD tube of less than 10 mm length. A

scaled-up working circuit which included the pressure sensor, amplifier,

transponder and antenna was built. Inductive transmission of power into the

circuit was also demonstrated. Other power input and signal output transmission

modes were explored, including direct wiring, radio frequency,and infrared.

Figure - Implantable pressure sensor model

showing location within fingertip.

|

Ralph Fingerspelling Hand

Jaffe, Schwandt, Anderson

Ralph is a computer controlled

electromechanical hand that serves as a tactile display for persons who are

deaf and blind. In operation, the deafblind user feels the hand as it moves and

interprets its motions as letters corresponding to the American One-Hand Manual

Alphabet, a technique known as tactile fingerspelling. The hand is controlled

by a microcontroller whose software translates incoming serial ASCII data into

control signals that operate eight servo motors. These servo motors pull on the

fingers' mechanical linkages causing them to flex. Ralph can use information

from a computer's serial port, modem, TDD, or computer interface to a optical

character recognition scanner, voice recognition system, closed caption

decoder, or stenography machine facilitating translation of e-mail, telephone

conversations, printed text, spoken words, subtitled television programs, or

classroom/conference/courtroom interactions into fingerspelling.

Commercialization of this technology is being pursued through collaborations

with an electronics company and a national research laboratory.

Figure - Ralph fingerspelling hand

|

Republished from the 1996 Rehabilitation R&D Center Progress Report.